Inox

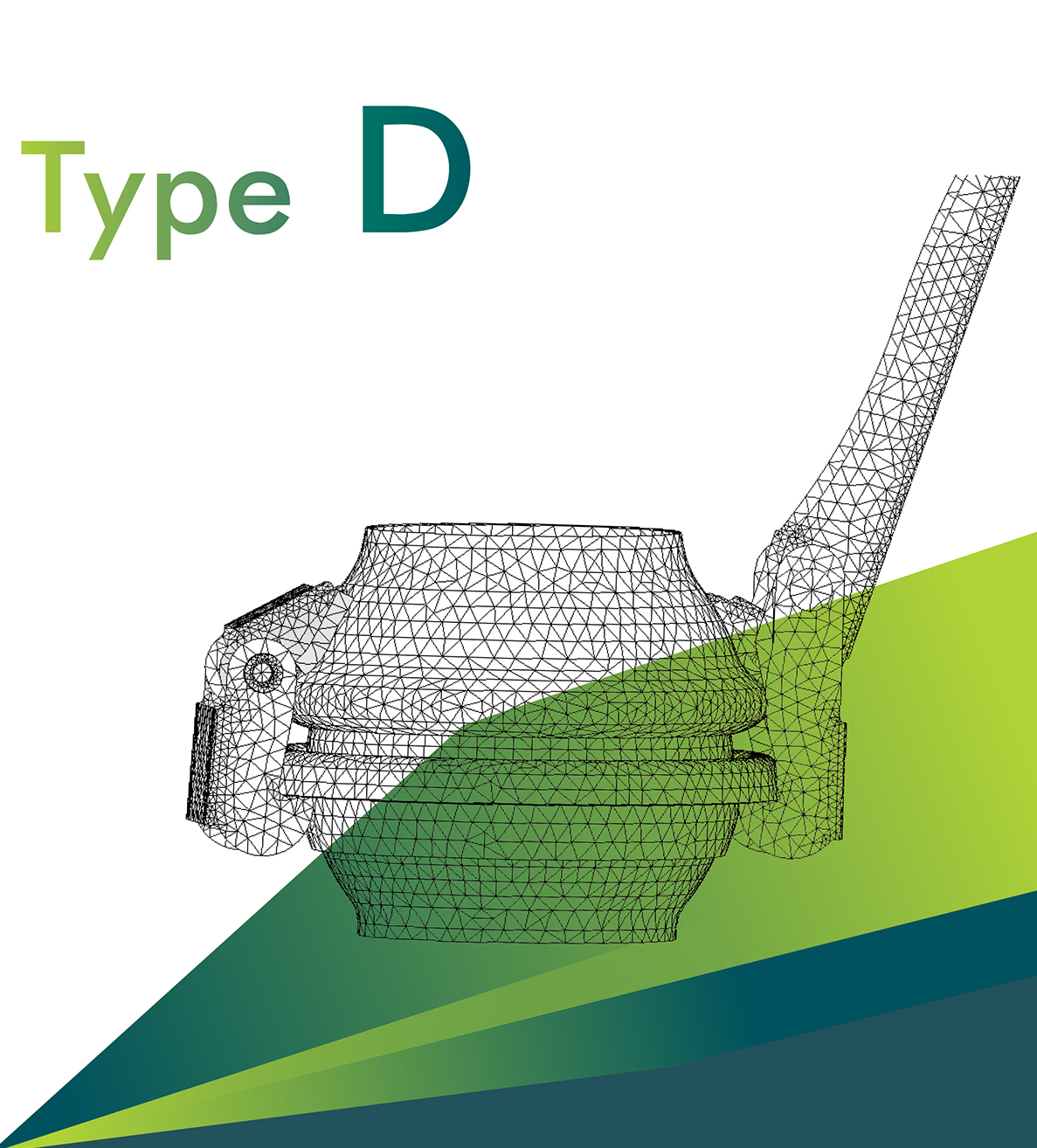

The first Dallai fitting was created in 1959 and features complete interchangeability with all similar fittings manufactured in Italy. The D-type range is made of iron, stainless steel and aluminum and, depending on requirements, a version with a safety lock can be supplied. It is mainly used in the field of irrigation and for a wide variety of applications such as drainage, sewage transport, road construction, in the food industry and in the chemical industry.

-

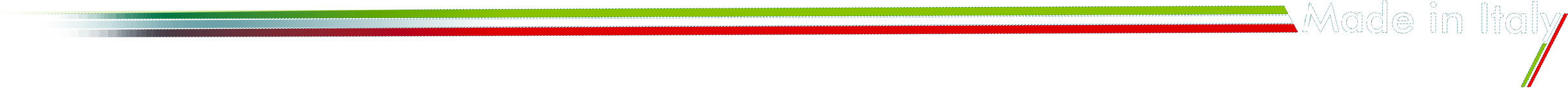

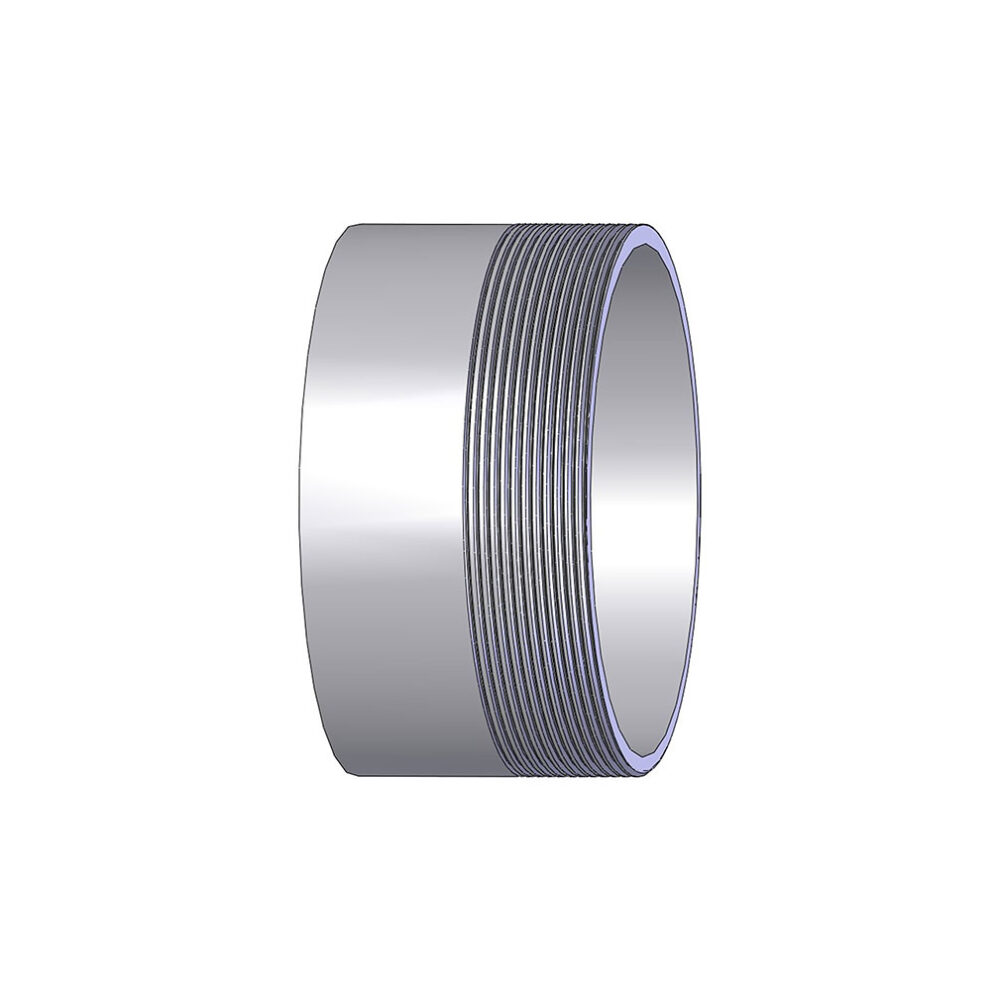

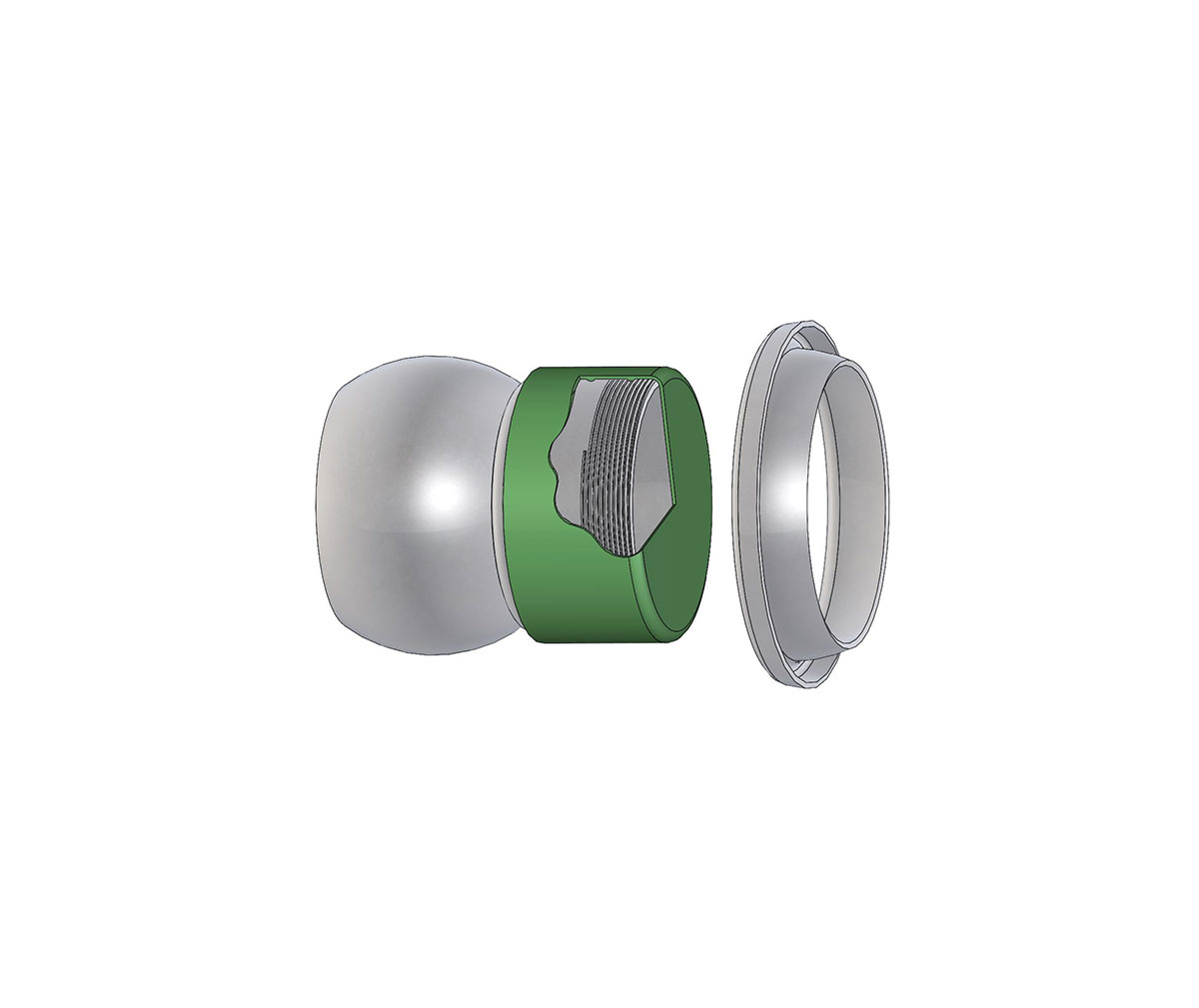

Inox Fitting

Ring

-

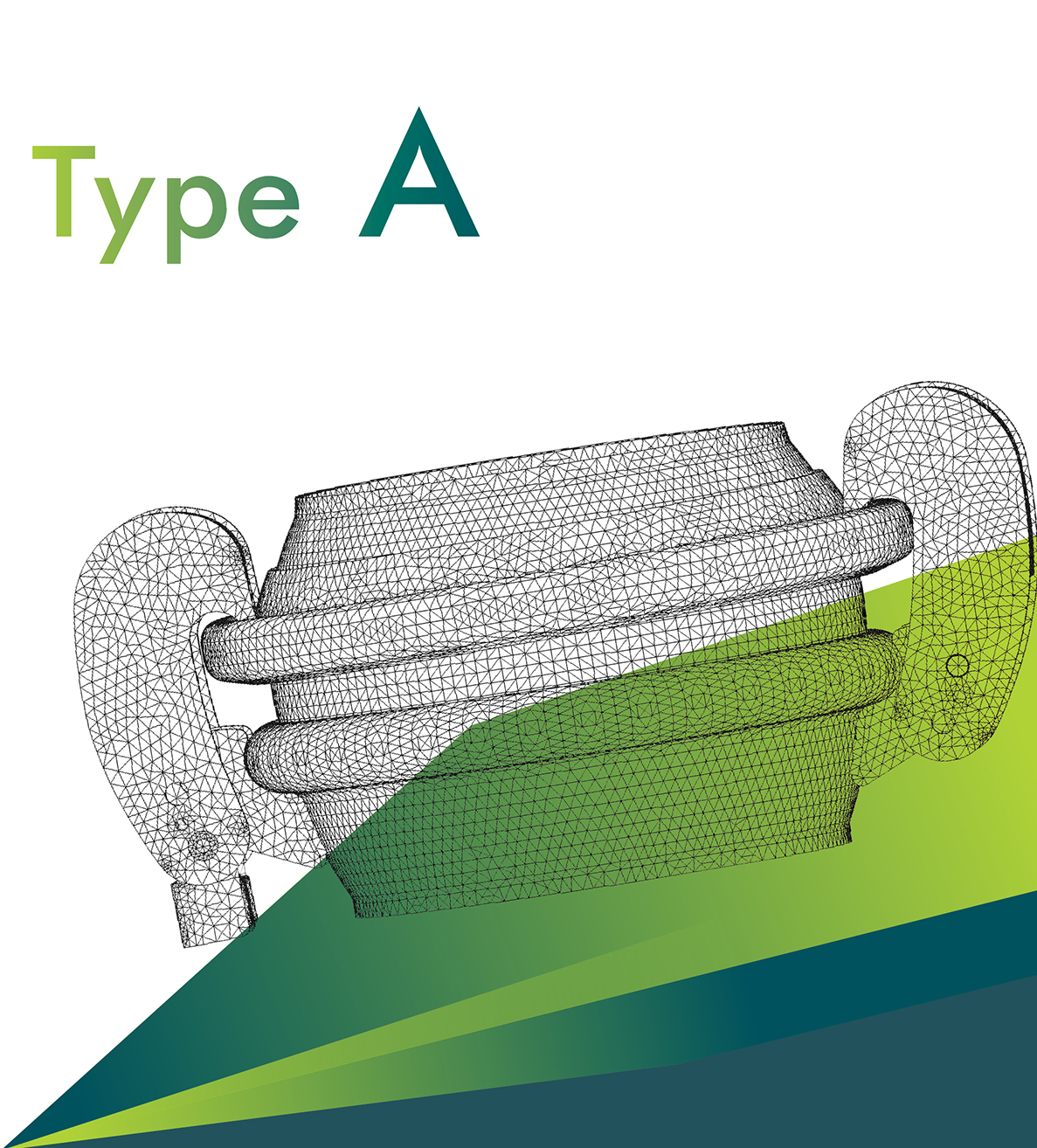

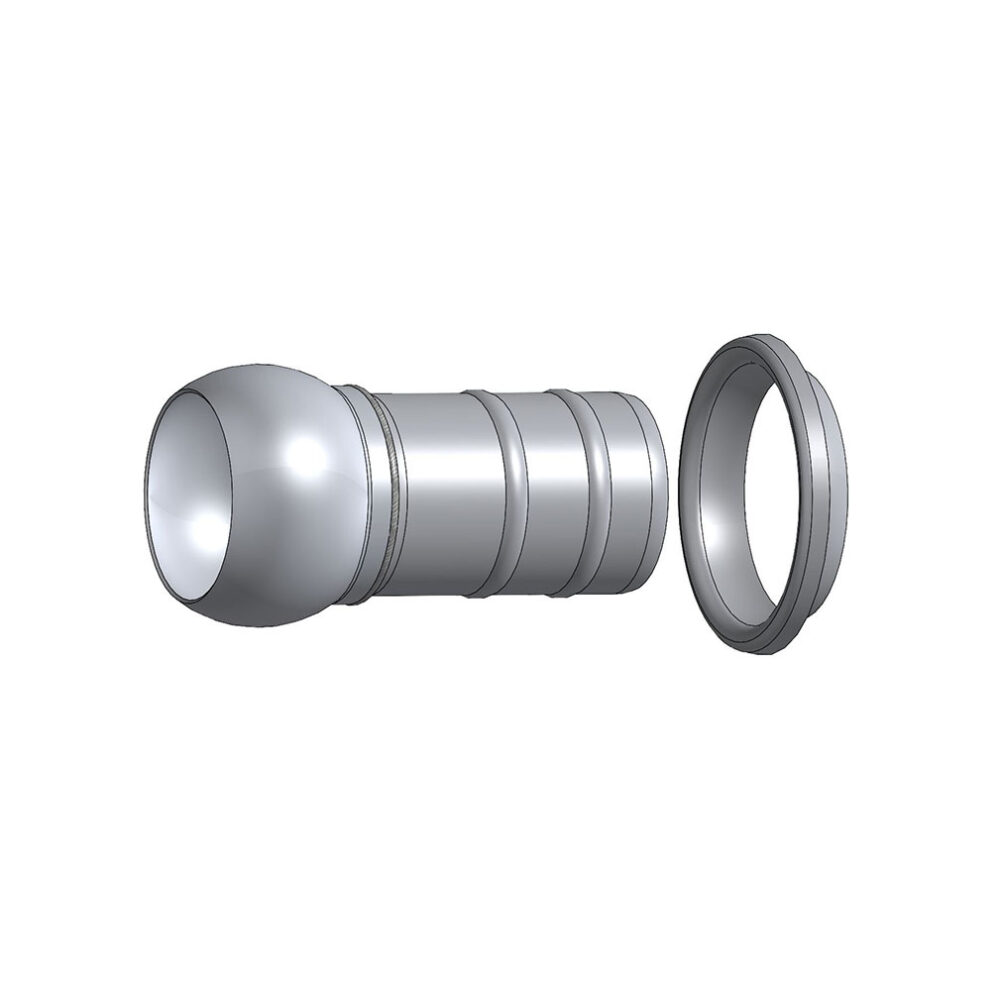

Inox Fitting

Male

-

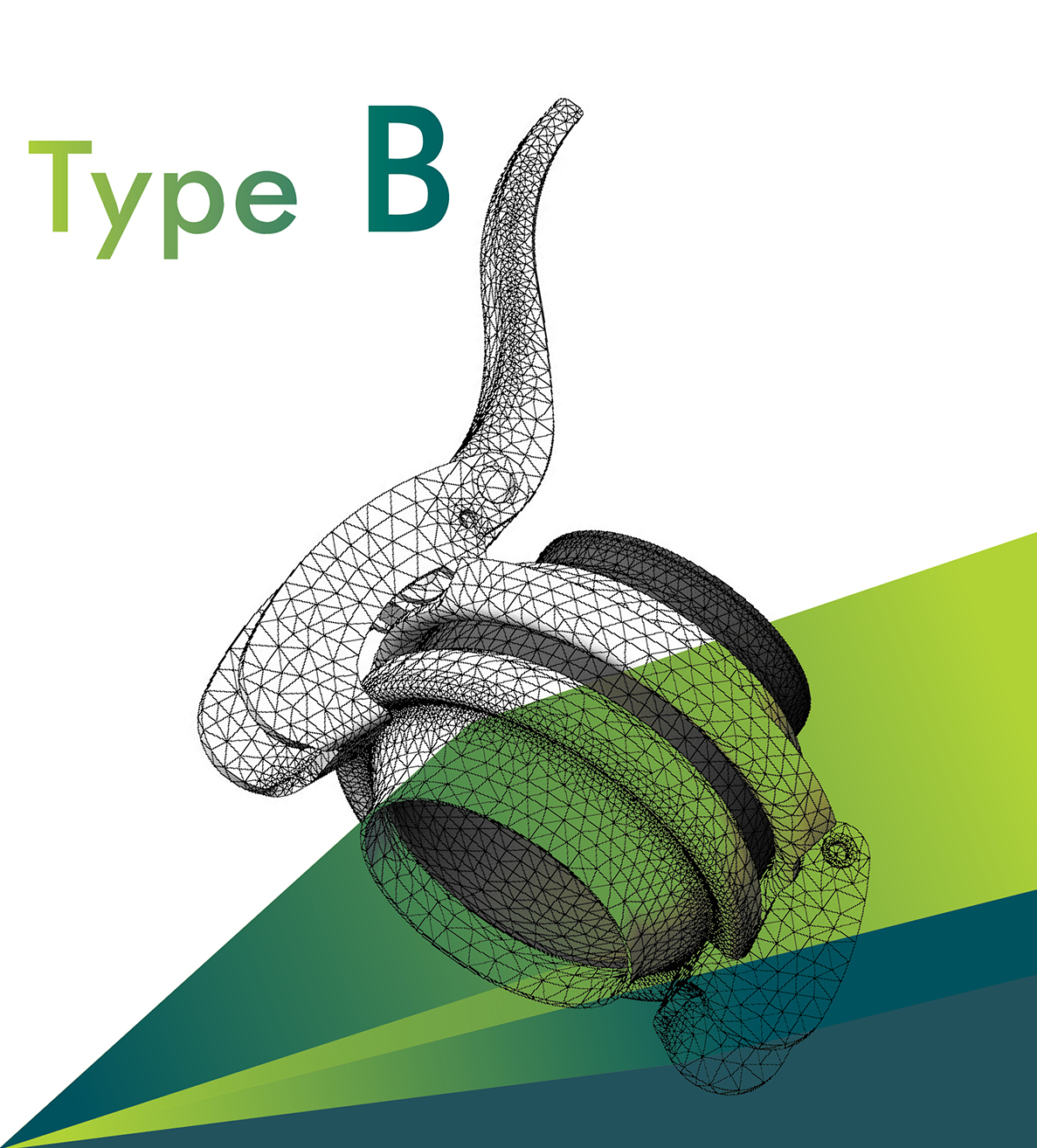

Inox Fitting

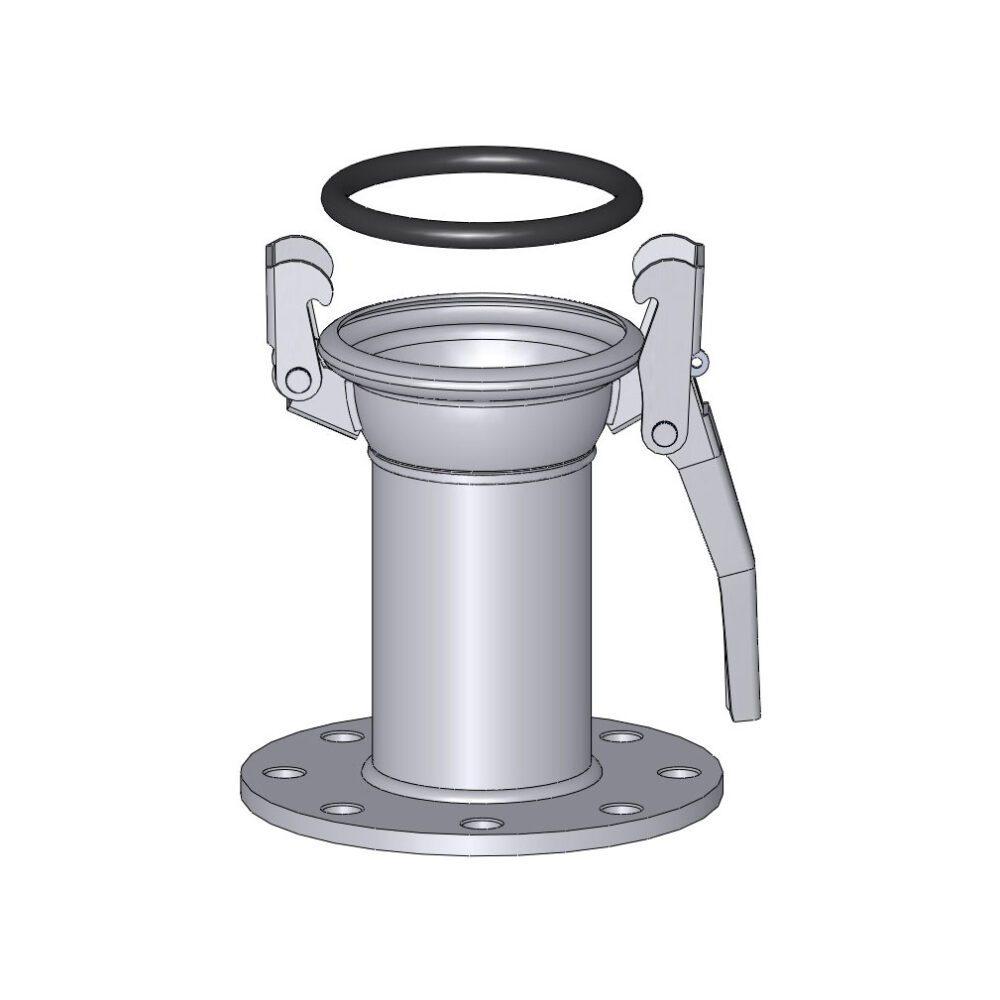

Female with rubber ring

-

Inox Cotter Pin

Stainless steel safety pin

-

Inox Gasket

Rubber ring spare part

-

Inox Fitting

Female with double handle and three hooks

-

Tappo Inox

Tappo femmina

-

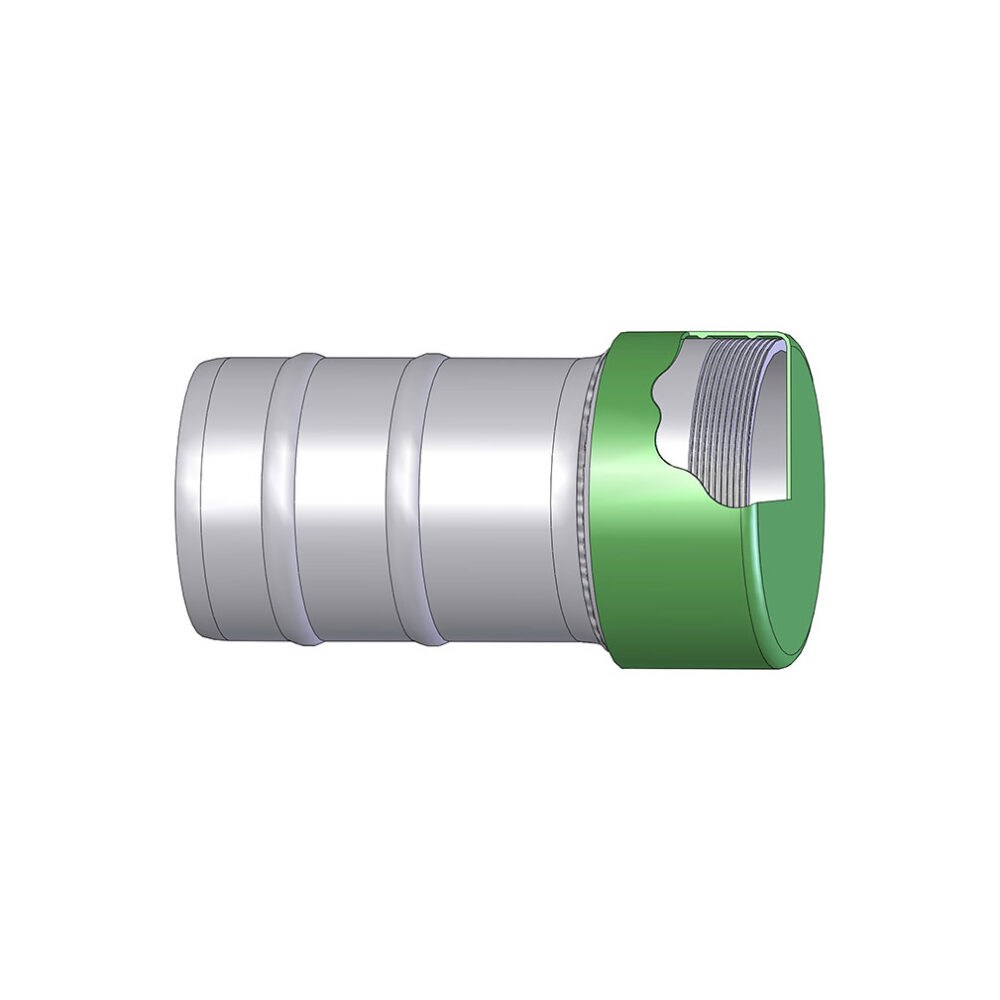

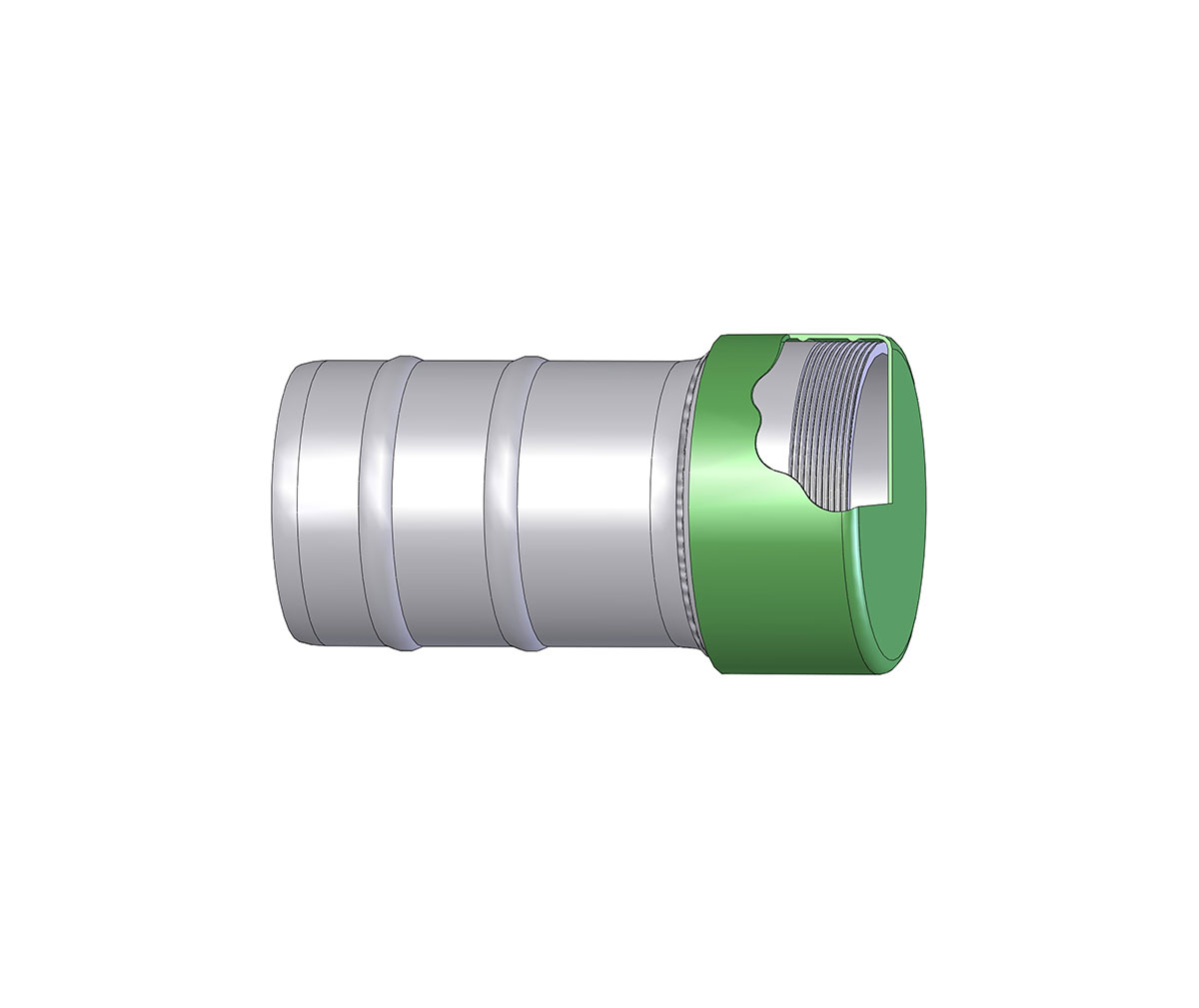

Inox Hose Holder

Male with hose spigot

-

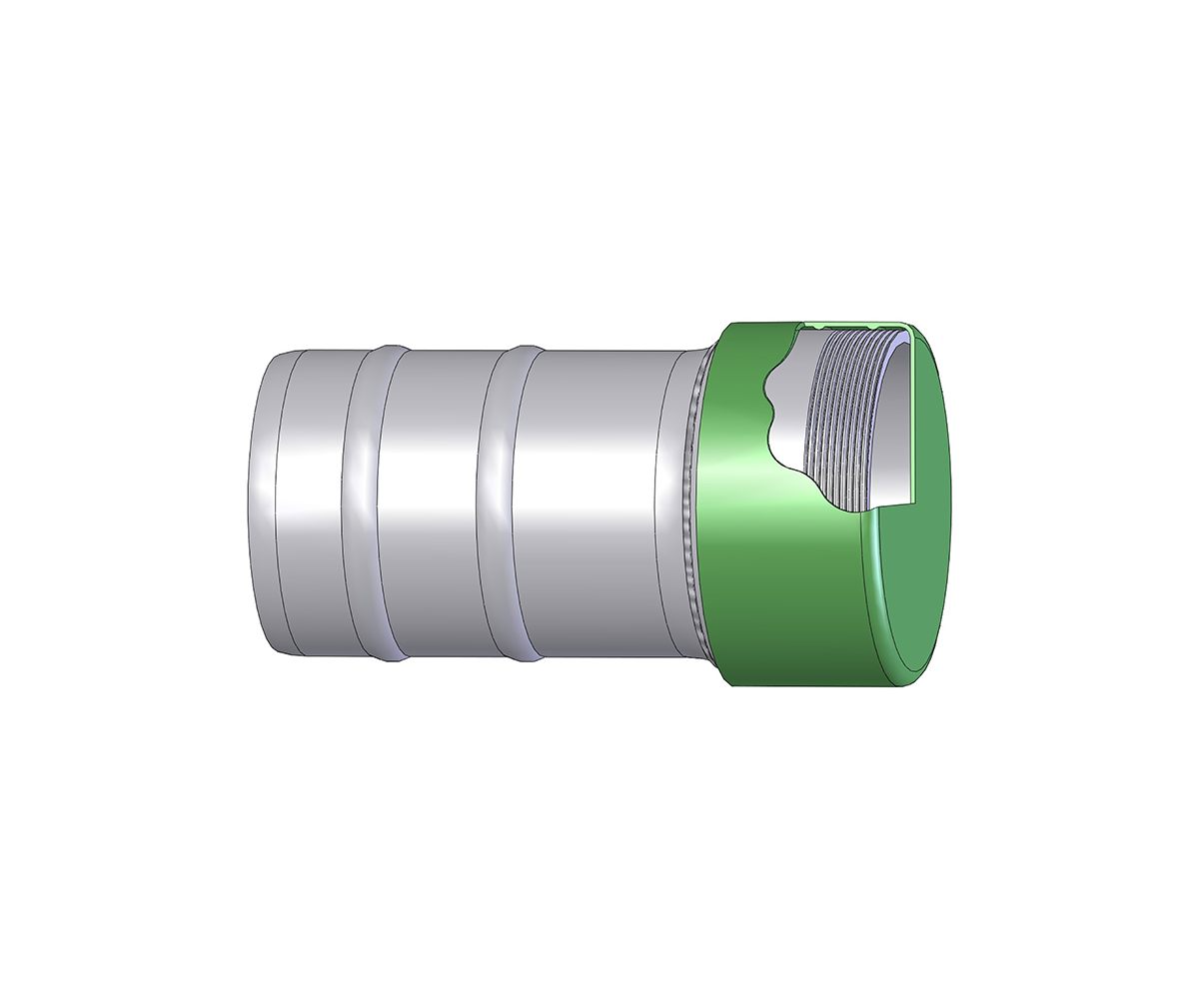

Inox Hose Holder

Female with hose spigot

-

Inox Thread

Male with ring with “GAS/BSTP” thread and cover-thread

-

Inox Thread

Female with “GAS/BSTP” thread and cover-thread

-

Inox Thread

Male with ring with inner thread

-

Inox Thread

Female with inner thread

-

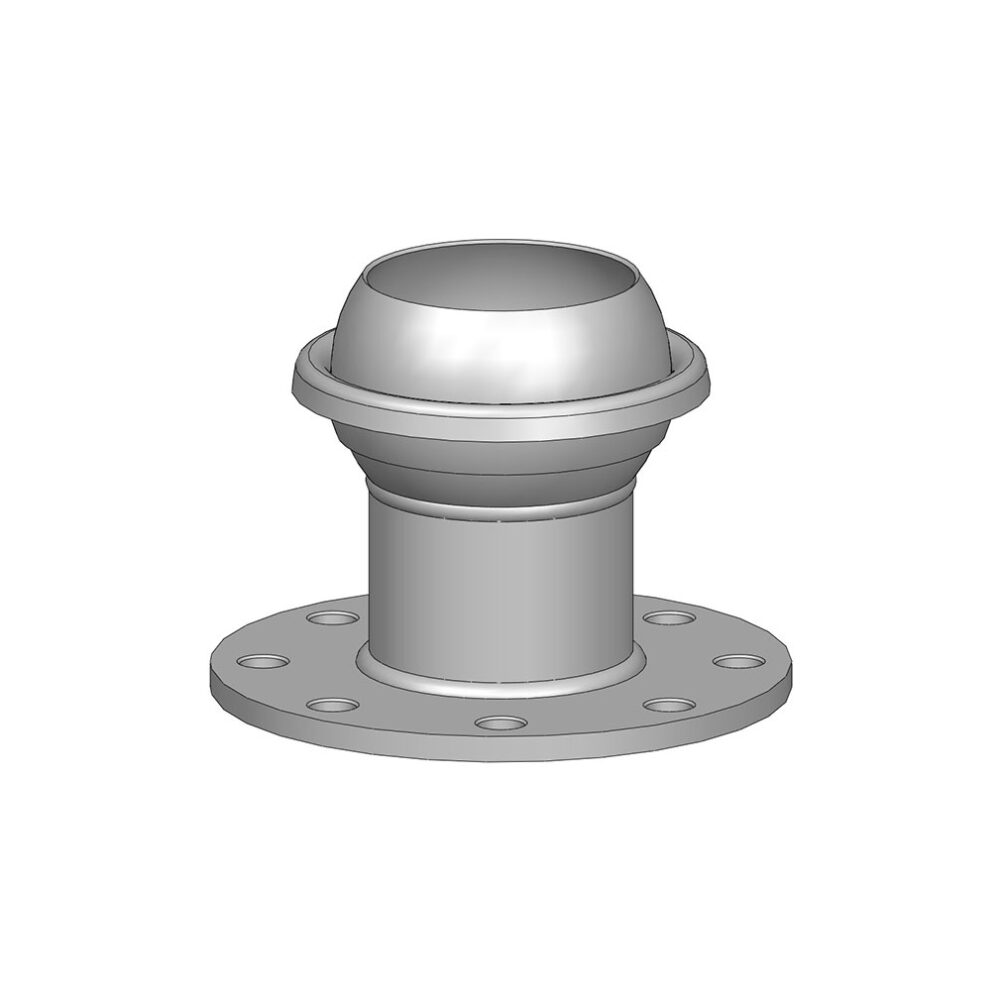

Inox Flange

Male with flange ** Derated flange EN 1092-1

-

Inox Flange

Female with flange ** Derated flange EN 1092-1

-

Inox Oversize Reduction

Male reduction

-

Inox Oversize Reduction

Female reduction

-

Inox Hose Holder

Stainless steel spigot with “GAS / BSTP” threaded pipe and cover-thread

-

Inox Thread

Stainless steel “GAS / BSTP” threaded stub pipe

-

Inox Hose Holder

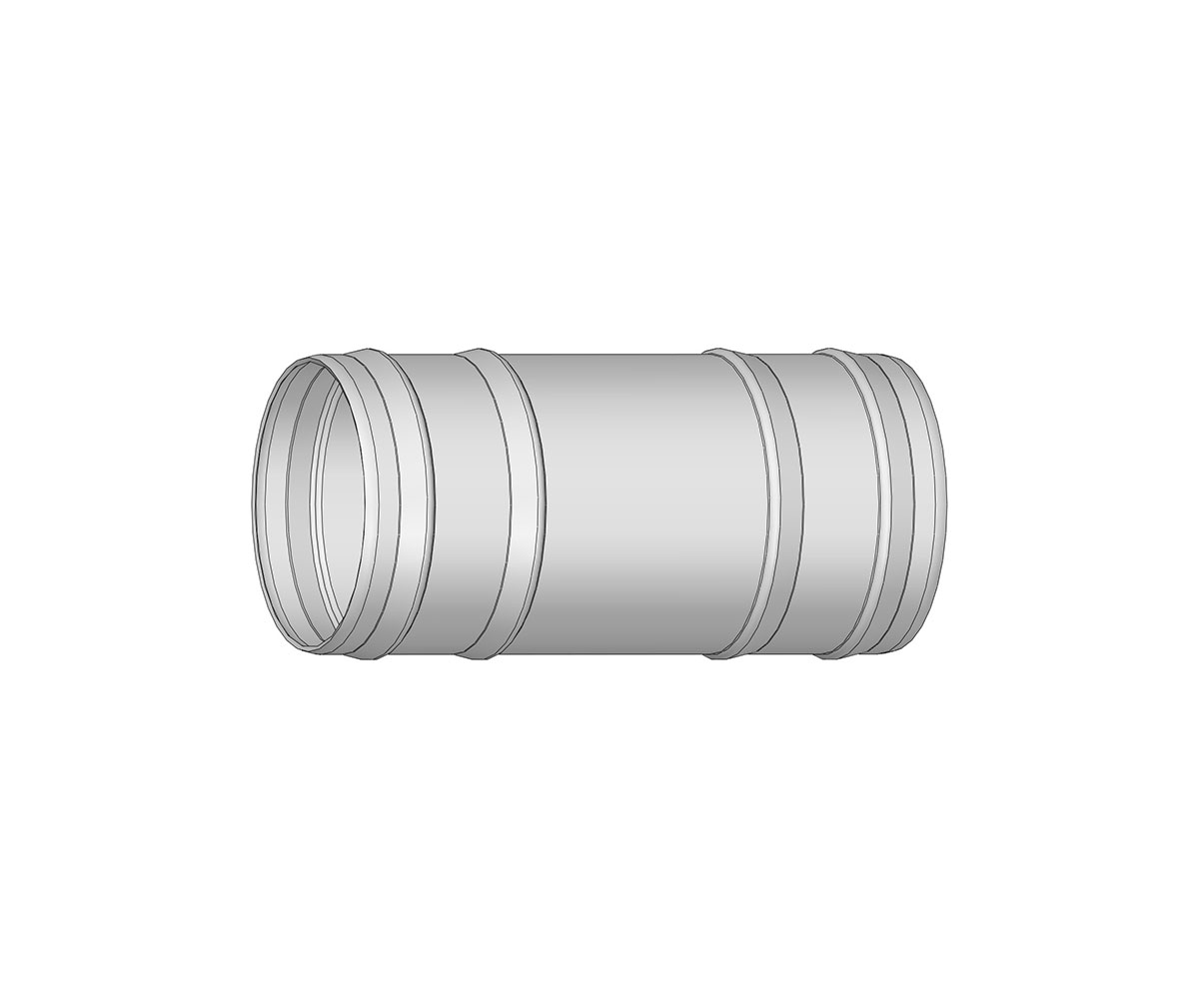

Stainless steel hose connection – hose connection type D

-

Inox Hose Holder

Stainless steel hose connection type D

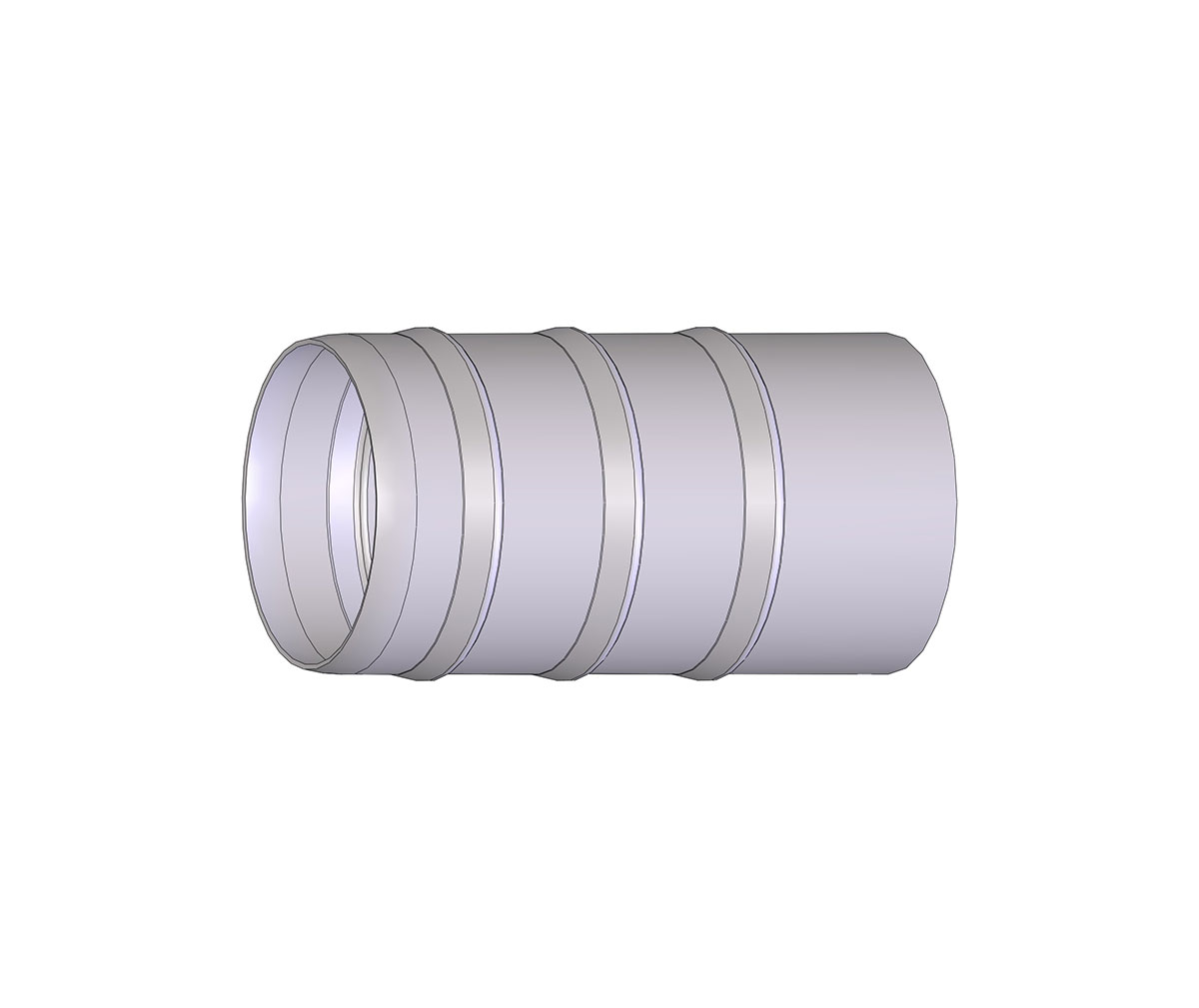

-

Inox Hose Holder

Stainless steel hose connection type B

-

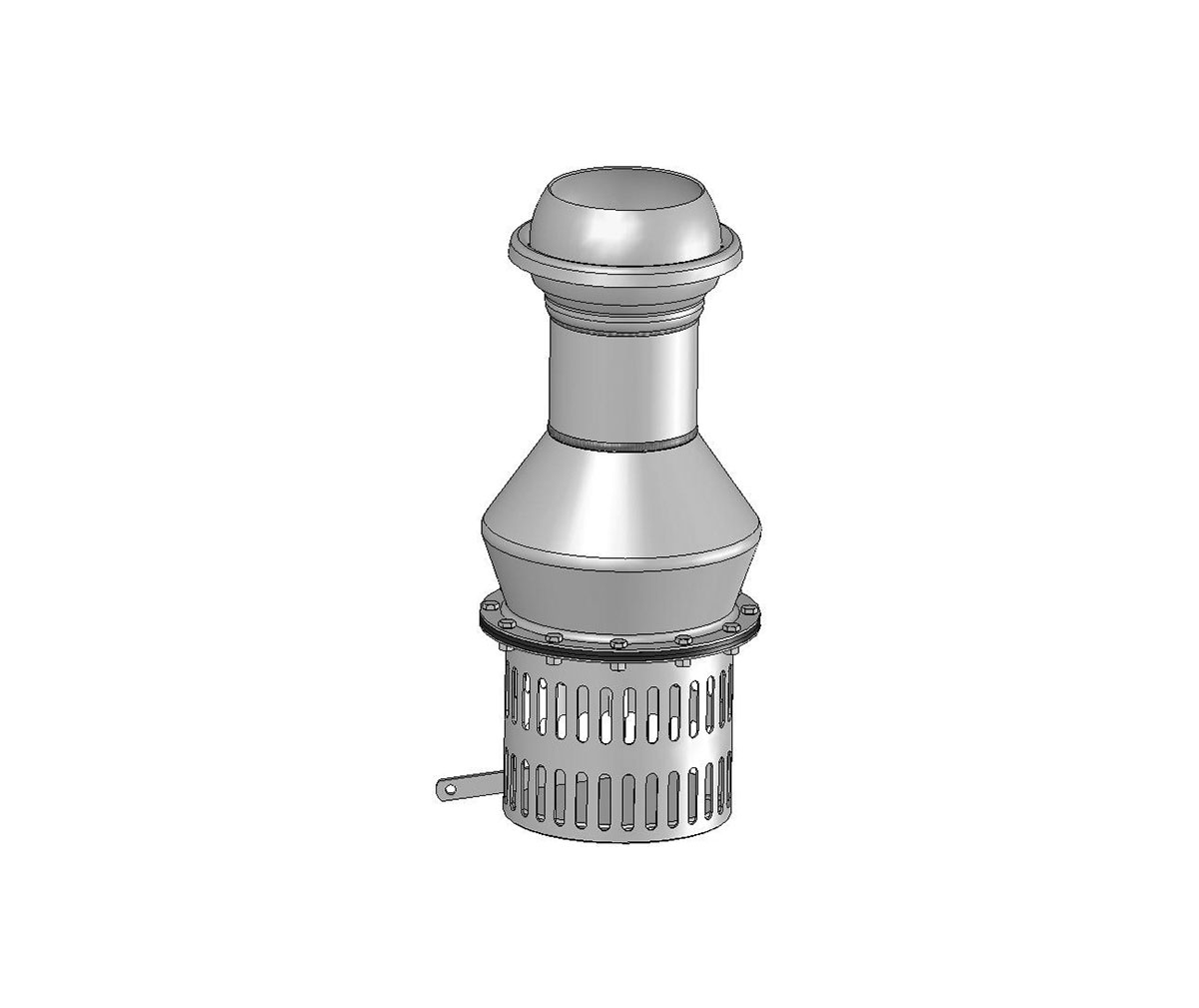

Inox Foot Valve

Foot valve with hose spigot

-

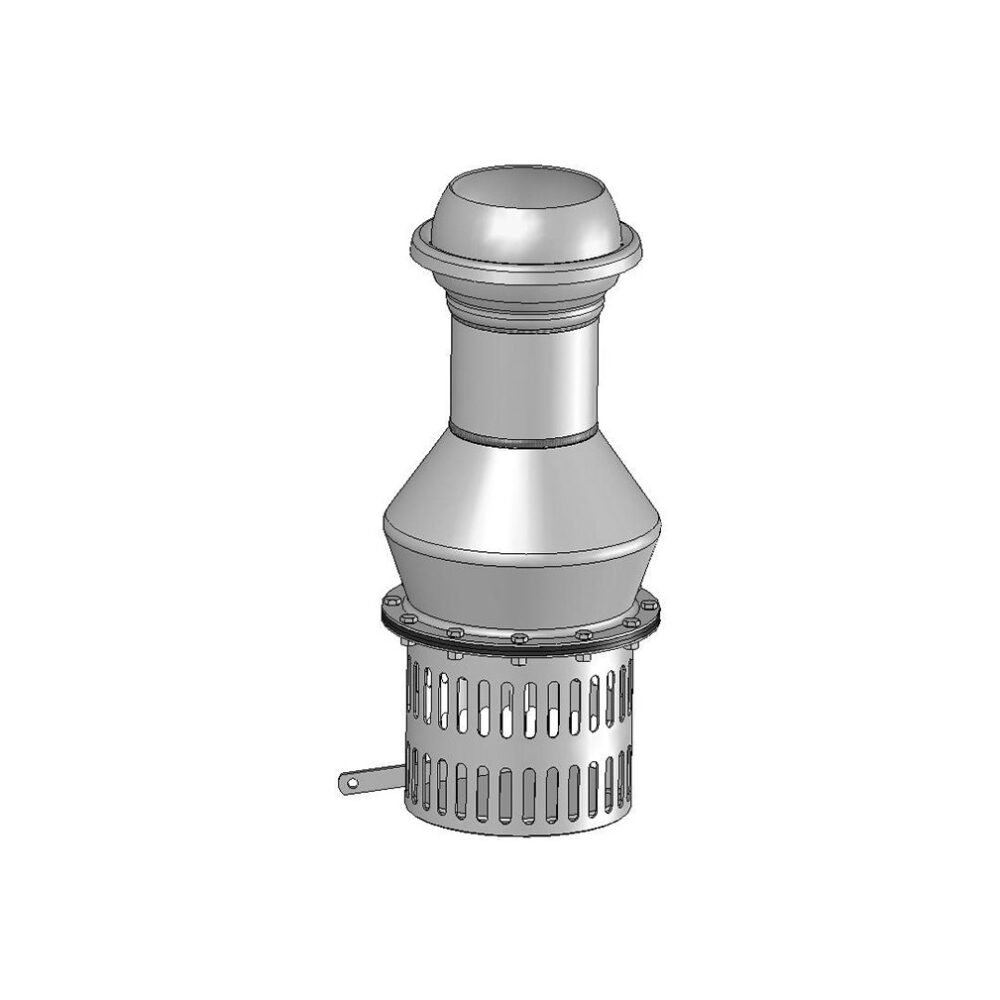

Inox Foot Valve

valve with male

-

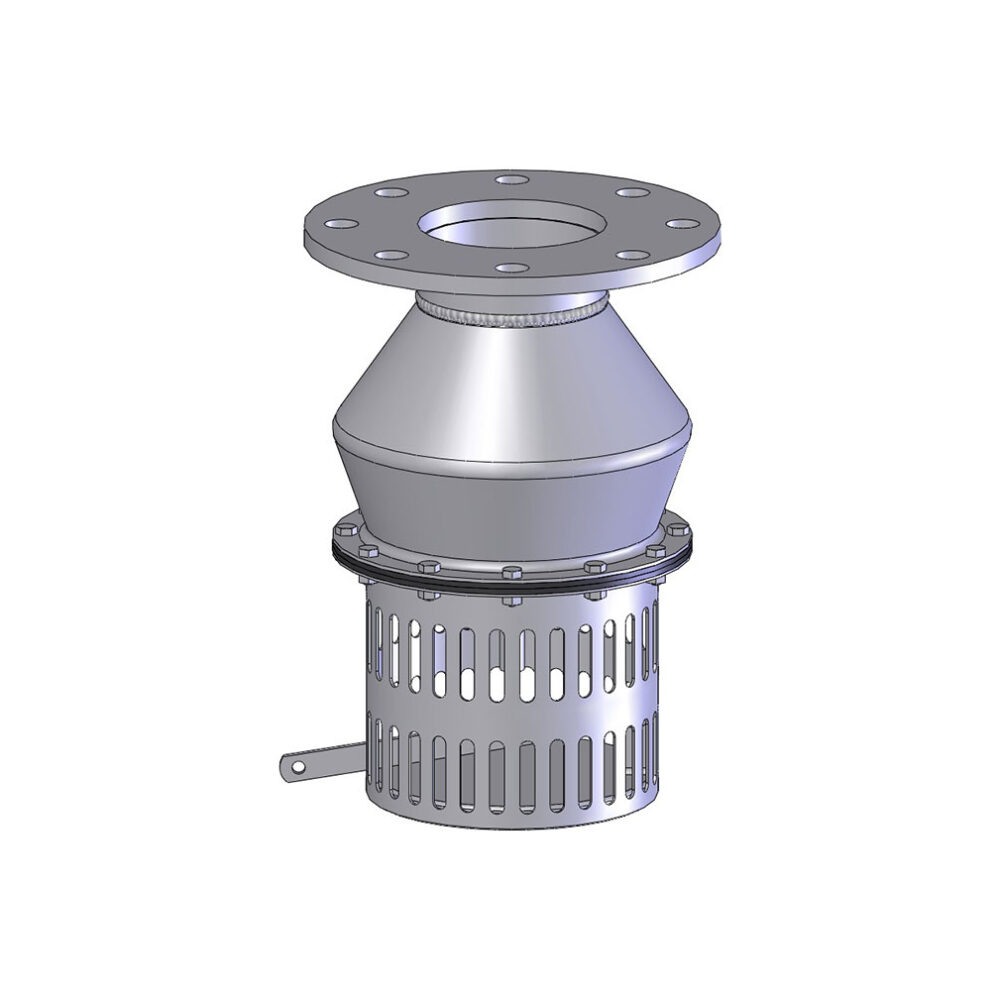

Inox Foot Valve

Foot valve with flange *EN 1092-1

-

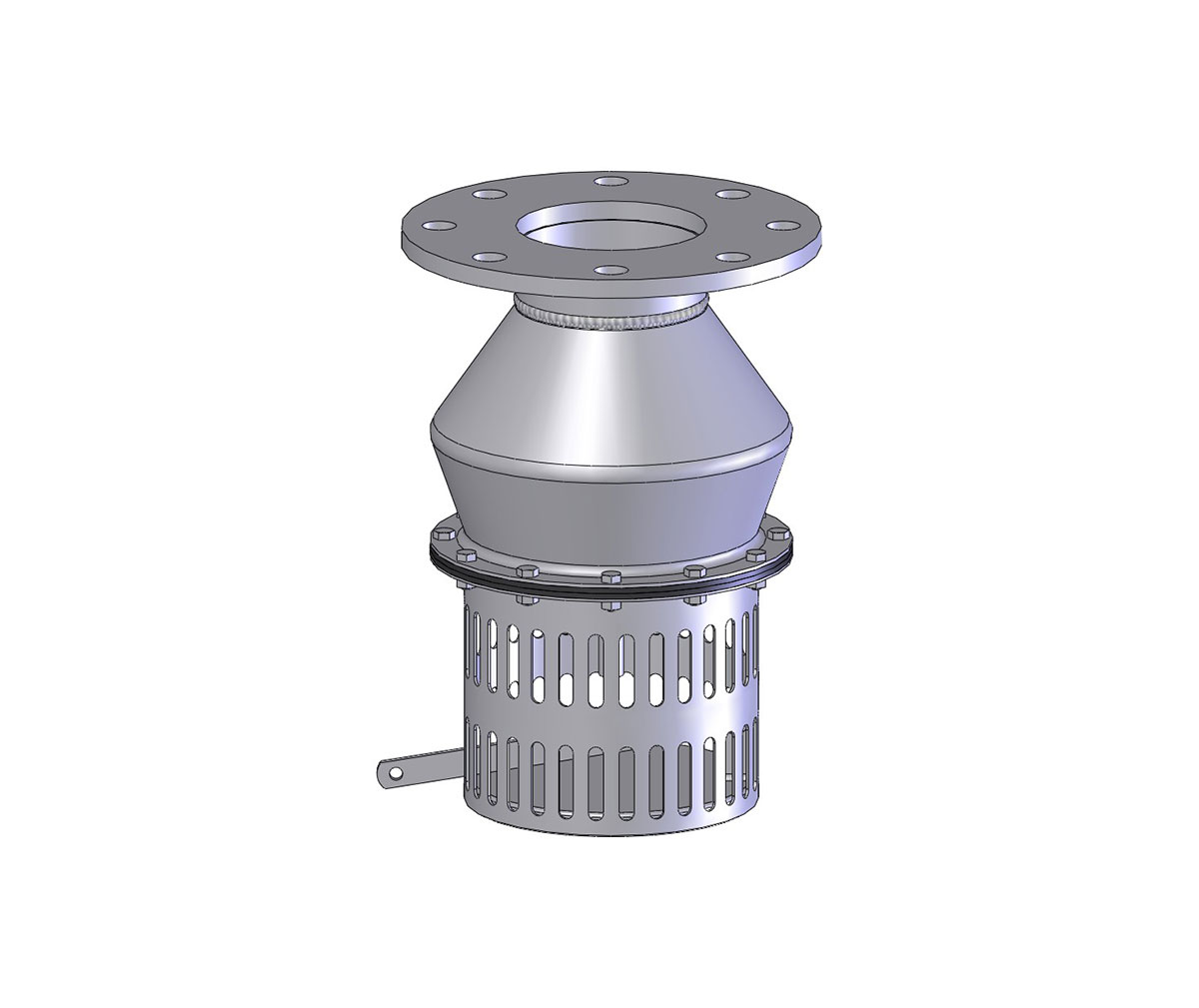

Inox Filter

Stainless steel strainer for self – priming pump with hosebarbed spigot

-

Inox Filter

Stainless steel strainer for self – priming pump with thread “GAS / BSTP”

-

Inox Filter

Stainless steel strainer for self – priming pump with with EN 1092-1/02° flared floating flange

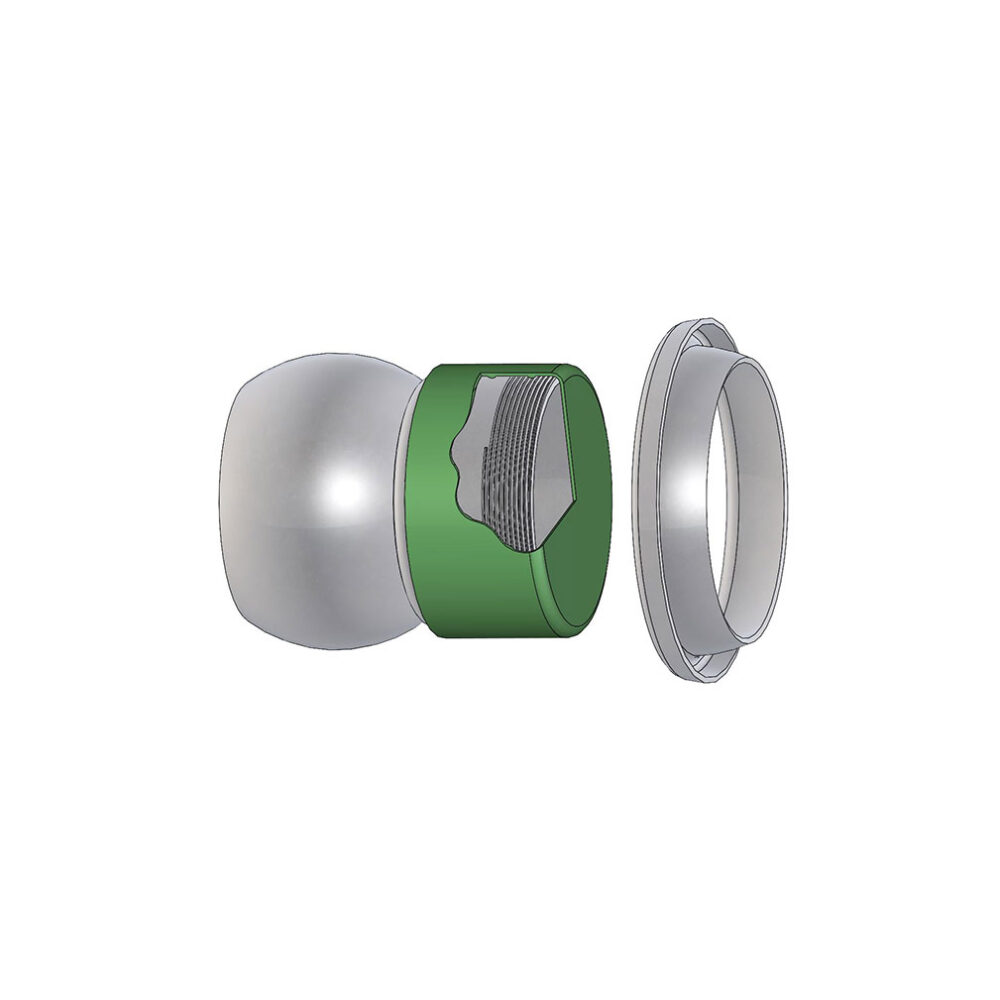

Procedure for assembling spherical fittings of type D Inox.

Place the male fitting against the gasket housed inside the female fitting.

Place the male fitting against the gasket housed inside the female fitting. Place the short hook in the outer ring seat.

Place the short hook in the outer ring seat. While holding the short hook in place, in the outer ring seat, open the handle for the long hook to sit in the outer ring seat.

While holding the short hook in place, in the outer ring seat, open the handle for the long hook to sit in the outer ring seat. Finally, once you have ensured that the male fitting is fairly aligned and does not run the risk of damaging the gasket, you close the handle to tighten the complete fitting.

Finally, once you have ensured that the male fitting is fairly aligned and does not run the risk of damaging the gasket, you close the handle to tighten the complete fitting.